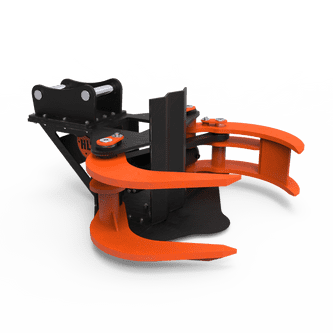

Description

- Hardox® 500 Blade

- Max Cut: 210mm

- Hardox® 400 Arms

- Oversize Cylinder

- Headstock included

- Fast cutting cycle

The TSH excavator tree shear range are Heavy Duty, professional work tools and are primarily available for use on any excavator between 4 and 30 tonnes, as well as being adaptable to fit on telehandlers and skid steers. The tree shear attachment / tree lopper is becoming increasingly used in many forestry applications due to the time and money saving advantages it offers. It is a single service attachment that works off your existing double acting hammer circuit. With one powerful hydraulic ram, this excavator tree shear is forgiving to imprecise alignment of the blade by the operator and consequently facilitates faster cutting.

The cycle takes just seconds per tree and you can immediately move the tree out of the way and move on to the next. Aside from being one of the fastest tree shears on the market, the TSH is also one of the easiest to maintain. With fewer moving parts than other tree shear models there is both less to go wrong and less to look after. With a removable and replaceable Hardox® HB500 blade, this excavator tree shear can also double as a hydraulic grab and is perfect for moving around timber, positioning telegraph poles or placing fence posts.

We supply these tree shears to fit your machine’s quick hitch, or to be directly mounted with removable pins. For additional manoeuvrability, we also offer the:

• TSH-R Fitted with a bolt-on, radial, piston driven 360° hydraulic rotator for full mobility.

• TSH-S Equipped with welded-on side brackets, the shear can be mounted with the blade running vertically, rather than horizontally – Ideal for de-limbing branches.

The simple cutting cycle involves:

1) Opening the grab,

2) Lining up a tree,

3) Pushing the blade in to the tree whilst closing the grab

4) Placing the cut tree down to one side

Hardox® 500 Blade

To ensure a long lasting, sharp cut we use HB500 on our tree shear blades – one of the highest-grade AR steels we use. Abrasion resistant steels have excellent durability and are incredibly tough, so they’re able to withstand abrasion and will hold their shape for longer. We use AR steels to protect vulnerable areas from wear and tear and in areas where the steel is required to be extra hard. Whilst these blades are bolted on and replaceable, they hold their shape for a very long time and only require an occasional sharpening if the edge has dulled.

Removable Bolt-on Blade

The bolt-on nature of the blade also means the tree shear’s grab can be used independently for handling timber, positioning telegraph poles or placing fence posts.

Cutting Diameter

The maximum cutting diameter on the 020-TSH tree shear blade is 210mm, but the realistic cut diameter varies depending on the hardness of the tree. We say this tree shear should be able to cleanly cut all 170mm diameter trees, and rough cut up to 210mm. We’ve charted the Janka hardness of some common British trees here with our estimated cutting diameters.

Hardox® 400 Arms

With the oversize cylinder producing so much force, we use Hardox® HB400 AR steel in the grab arms to ensure rigidity and prevent deformation.

Extra powerful cylinder

There are several tree shear designs on the market, some use a grab with hydraulic scissor blades below, some use a chainsaw. Our tree shear is simpler, with fewer moving parts and therefore fewer parts that can go wrong.

The performance of our tree shear is dependent on the pressure produced by the carrier machine, with that pressure determining how much power the hydraulic cylinder can exert to pull the blade through the tree. Operating at full capacity (@ 320 bar / 4640 PSI), our 020-TSH cylinder can generate a staggering 16.4 tonnes of force.

*Please check your machine’s spec as most machines in this class operate pressure @ ~200bar, meaning closer 10 tonnes of force.

Mast Support

This support is fitted to help keep the tree straight and prevent it from falling back towards the cab. With the legs closed tightly, the mast ensures the tree is held firmly in place.

Supplied to suit your machine

Our excavator tree shears come with a headstock fabricated for any linkage required to fit your excavator. Whatever you need, we can fabricate it. Whether it’s a going on a quick hitch, requires a direct mount setup, S-link, Klac, Morin, Harford® Safelock, or anything else.

We hold our tree shears in stock, so all we need to do is cut the headstock parts from sheet metal and bolt it on. Call us today to check our current lead time.

Please watch the Video below of our 060-TSH Tree Shear in action

NB: An optional additional side bracket is available on non-hydraulic rotation models. It is a lower cost option that enables the machine’s quick hitch to pick up on the side of the shear and thus changing the orientation of the blade at the front. Ideal for horizontal branches!